Powering the future of fusion energy and semiconductors through extreme thermal innovation.

Get in TouchWe are developing a compact, single-component cooling device that transforms extreme, localized heat into a manageable thermal load—critical for applications like fusion reactors and next-generation semiconductors.

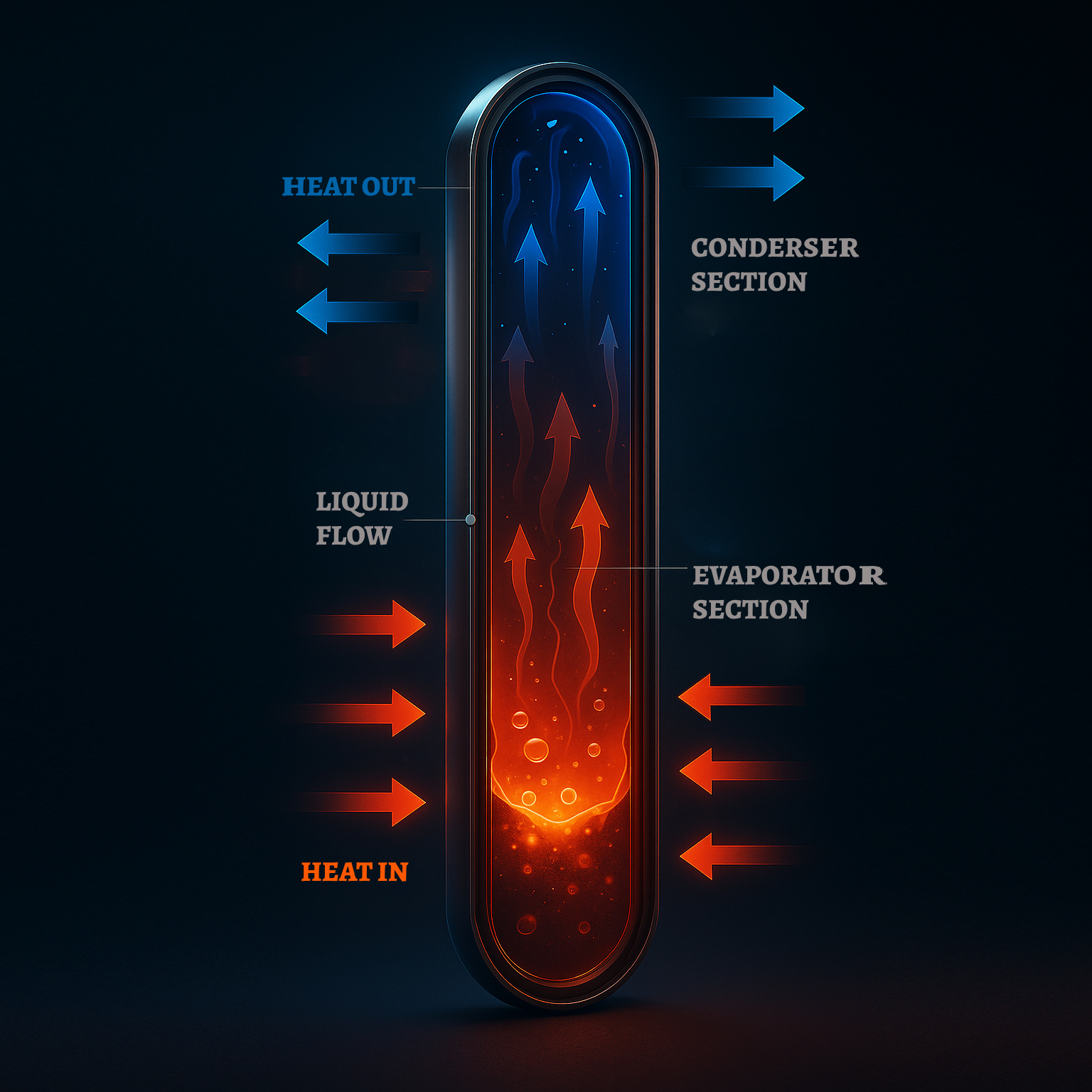

We build on the proven principles of heat pipe technology — a highly efficient method for thermal management used across aerospace, electronics, and energy sectors.

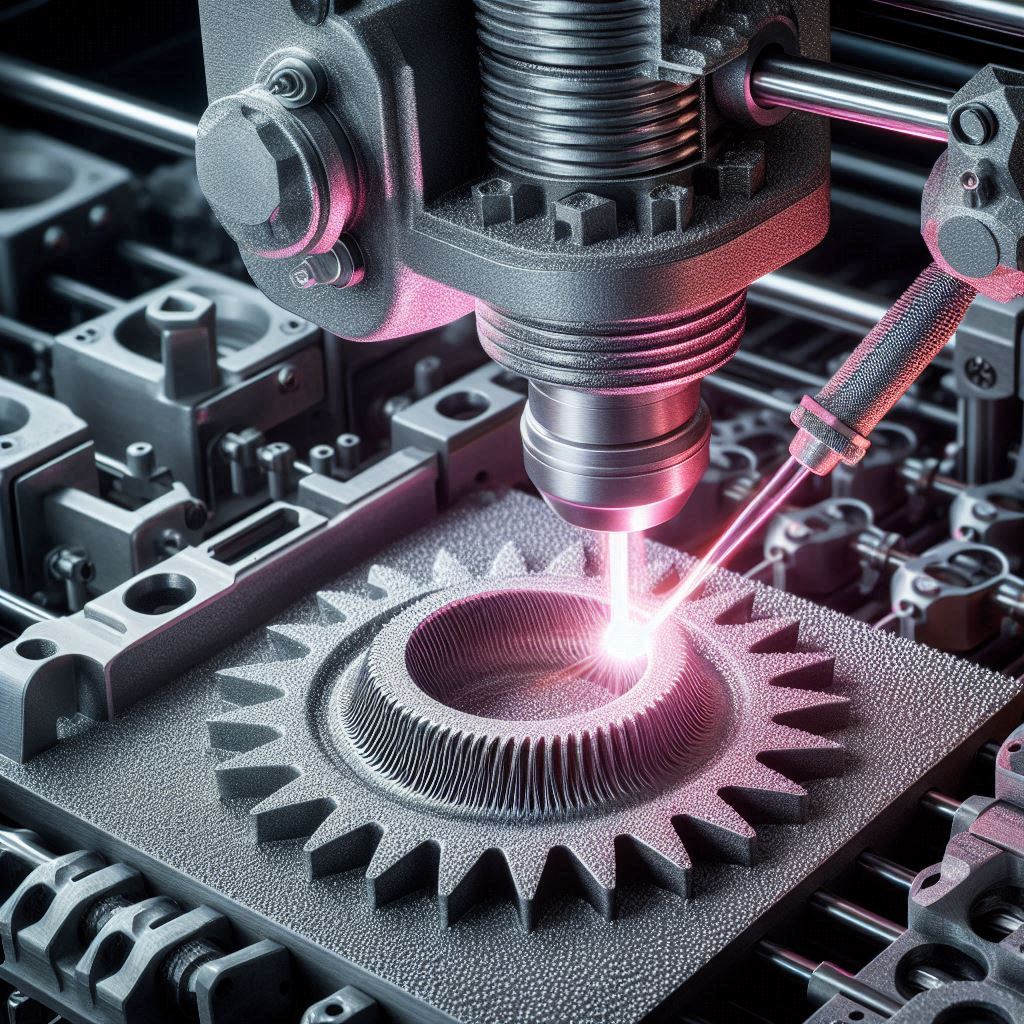

We leverage advanced metal 3D-printing to manufacture complex, high-performance thermal systems with unmatched precision and scalability.

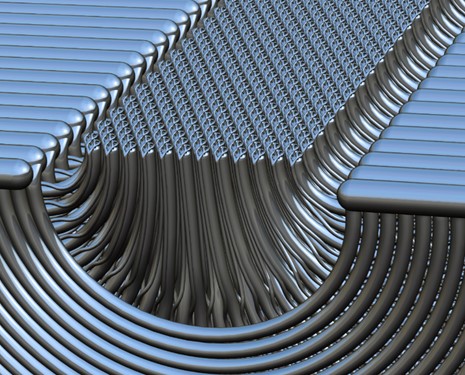

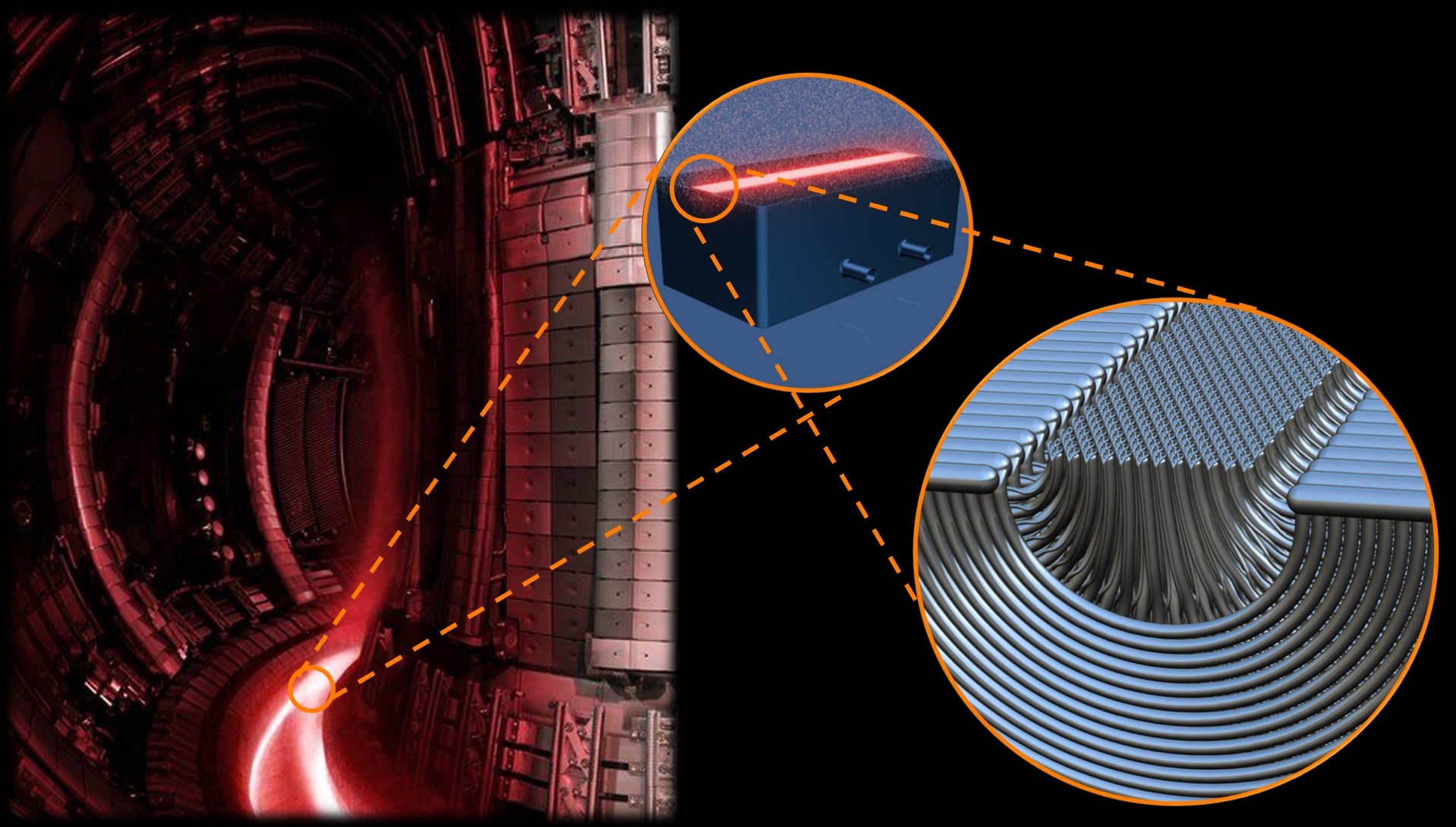

By integrating both technologies, we’ve developed the 3D-Printed Heat Pipe Array — an innovative solution capable of managing extreme heat loads with exceptional efficiency and adaptability. And it does not require assembly-just a simple coolant in/out interface.

Our innovation removes a key thermal barrier across both energy and information technology—accelerating two of the 21st century’s most transformative revolutions.

Our 3D-Printed Heat Pipe Array is designed for the extreme heat fluxes at divertor strike points in fusion reactors, enable continuous, net-positive fusion reactors-ushering in an era of clean, abundant, and reliable energy. The world would no longer rely on fossil fuels.

Improving cooling for next-gen semiconductors. Our 3D-Printed Heat Pipe Array will enable high-performance semiconductors to operate at higher frequencies with improved termal stability, unlocking the next generation of AI, communications, and defense systems.

Because we are not alone